what are the three basic areas of a machine that require safeguarding

That point where work is performed on the material such as cutting shaping boring or forming of. The point where work is performed on the material such as cutting shaping boring or forming of stock.

Oshacademy Course 154 Machine Safeguarding Basic Module 1

What are the three basic areas of a machine that require safeguarding.

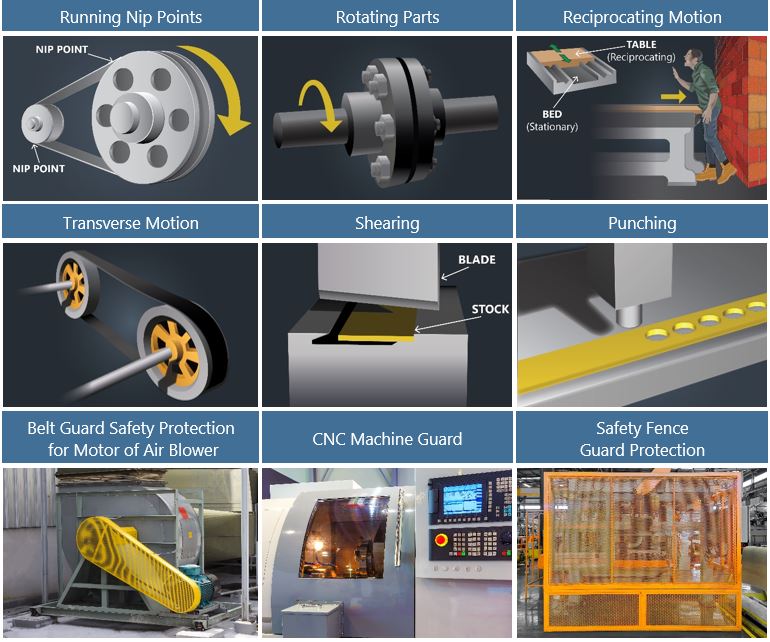

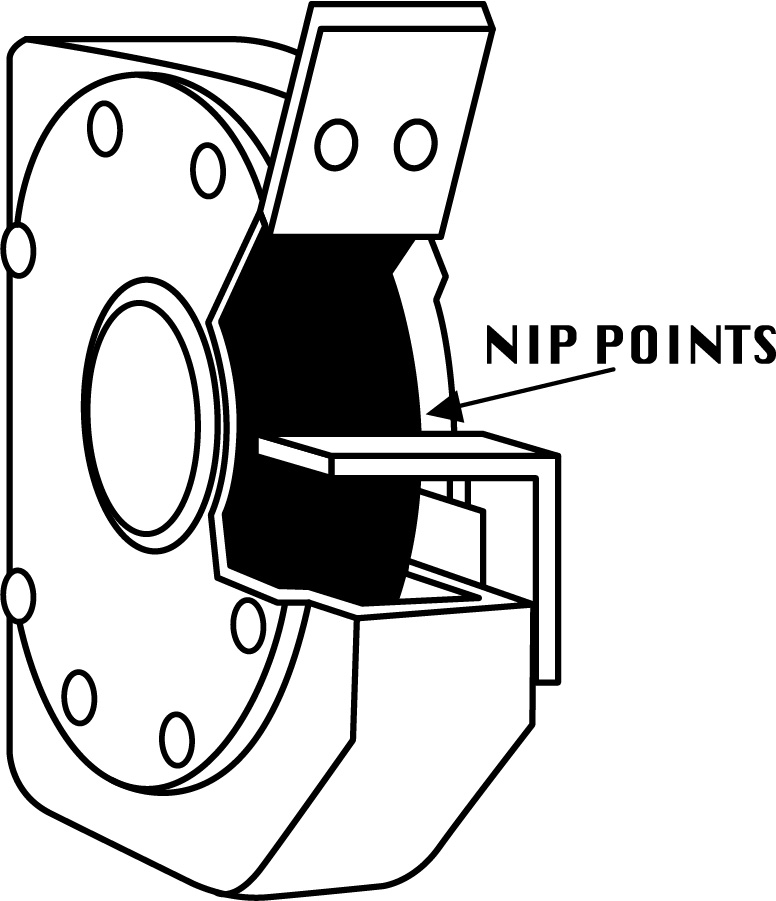

. Recent fatalities involving confined spaces demand that these areas be given more attention to reduce risk of injury or loss of life. Dangerous moving parts in three basic areas require safeguarding. The point of operation the power transmission device and the operating controls.

Machine safeguarding helps protect. Mechanical hazards typically involve dangerous moving parts in the following three basic areas. The safeguard must prevent hands arms or any other part of a workers body from contacting.

Dangerous moving parts in three basic areas require safeguarding. There are three basic types of motion. Machine Guarding eTool All machines consist of three fundamental areas.

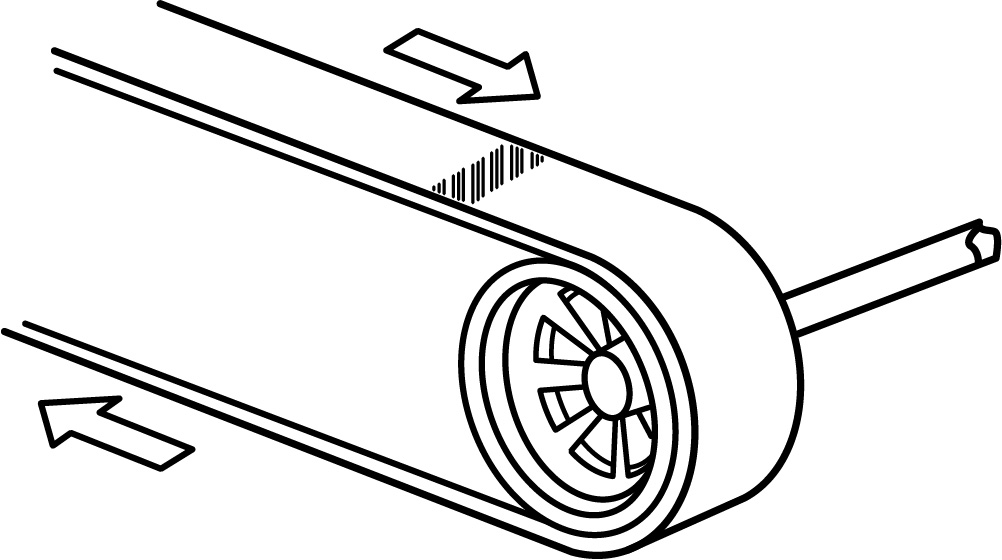

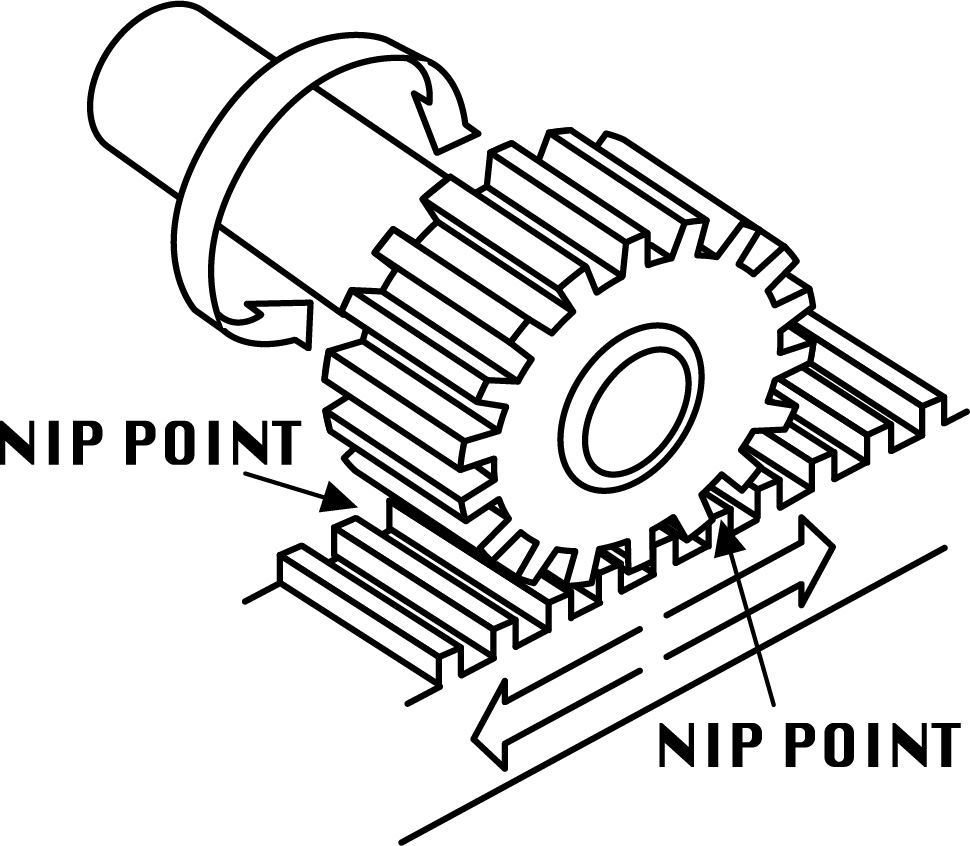

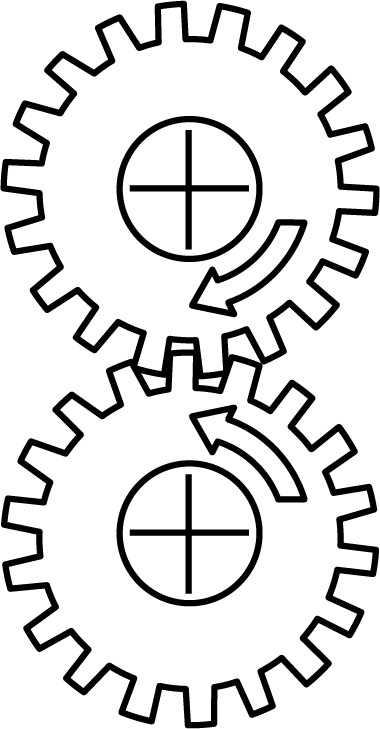

That point where work is performed on the material such as cutting shaping boring or forming of. Rotating reciprocating and transverse. Machine safeguards must meet these minimum general requirements.

The point of operation. Despite all machines having the same basic components. Automated Feeding and Ejection Mechanisms.

Dangerous moving parts in three basic areas require safeguarding. What are the three basic areas of a machine that require safeguarding. The point of operation.

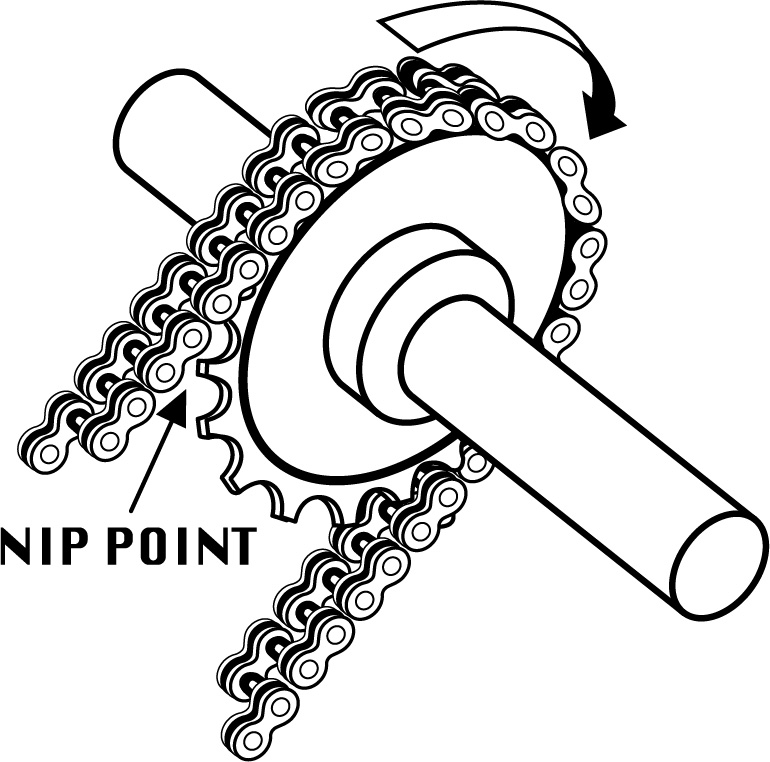

Rotating motion can be dangerous. Guards these are physical barriers that prevent contact. Well on a machine there are 3 fundamental areas which are the point of operation the power transmission device and the operating controls.

Devices these limit or prevent access to the hazardous area. The point of operation. The point of operation the power.

See Details 3Machine Guarding. Following three basic areas require safeguarding. All machines consist of three fundamental areas.

Point of Operation Power Transmission Apparatus Other Moving Parts Question 2. Even smooth slowly rotating shafts can grip clothing and.

Osha Requirements Machine Guarding Grainger Knowhow

Machine Guarding For Workplace Safety Safesite

Chapter 1 Basics Of Machine Safeguarding

Machine Safeguarding By Location And Distance

Machine Guards Eliminate Hazards For Employees Article The United States Army

1 Objectives Objectives Course No 204 Machinery And Machine Guarding Standards Course Identify Basic Machinery Terms Identify Common Machines Found Within Ppt Download

Guards Methods Of Machine Guarding

Osha Requirements Machine Guarding Grainger Knowhow

Osha Safe Guarding Poster Compliance Poster Company

Risk Assessment A Practical Guide To Assessing Operational Risk Ppt Video Online Download

The Guarded Truth Answers To Machine Guarding Compliance Faqs Ensafe

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Templates Machine Safeguarding Program

Six Types Of Machine Safeguard Devices

Managing Health And Safety Lecture 2 Plan 1 Occupational Safety And Health In Russian Federation 2 Labour Legislation 3 International Management Systems Ppt Download

Osha Requirements Machine Guarding Grainger Knowhow

Minimize Conveyor Injury Risks With Safeguarding Industrial Equipment News